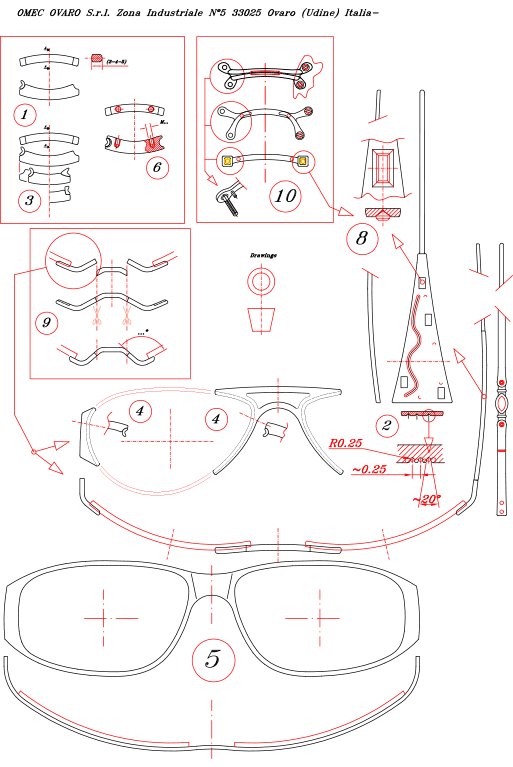

Below is a list of useful information on the types and quality of the components we are currently able to manufacture:

Below is a list of useful information on the types and quality of the components we are currently able to manufacture:

- we are able to build moulds and moulded parts with no shearing marks, or the least evident possible, even if the small parts are just 3 or 4 mm thick;

- we are able to produce small parts with chisels to perfect aesthetic levels;

- we are able to produce and mill small parts to the rim shape you desire;

- we manufacture small parts with the coupling zones milled using continuous 5-axis machines;

- we are able to produce perfectly bent fronts with the option of also supplying the bending control equipment to allow the client to verify the quality at his own facility;

- we are able to implement holes and threads or continuous 5-axis milling on small moulded parts, or continuous 5-axis milling directly from a wire or sheet;

- we are able to design eyewear with simply a technical drawing and/or sketch at our disposal;

- we are also able to implement rhinestone seats on small parts during the moulding phase, or on finished parts using continuous 5-axis work centres;

- we are able to produce formed and tumbled closing block joints with the pantoscopic angle already curved or bent during the moulding phase;

- we are able to supply small metal parts for “3 PIECE” eyewear with screws and rod for lens reference or for acetate rims.

Below are the designs related to the above information points.

Upon request we can provide: delivery times, quotations, prices, payment terms and our General Conditions of Sale.